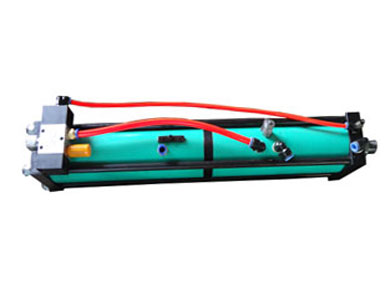

MT型气液增力缸(预压式分体组合型)

纯气动的分体组合式ODMT气液增力缸,由气液增力装置MES及工作缸MHZ组合而成,最大6bar或8bar压缩空气驱动,即可产生2KN-2000KN冲压力。液压由集成存于MES内,无需液压系统。结构简单,配有绝对严格的气液隔离密封。

控制与一般的串联双作用气缸控制相同,简便可靠,能耗低,无冲击,无噪声。

每一工作过程由如下三个行程段构成:

(1) 纯气动的快进行程;

(2) 气液增力的力行程;

(3) 气动的反回行程。

应用范围:MT型气液增力缸可用于力行程很大并且/或安装空间狭小的应用场合。一套MT型气液增力缸由一只气液增力装置MES和一只或几只工作缸构成。工作缸有MAT型气液缸或MHZ型特殊液压缸两种形式,气液增力装置MES与工作缸MAT或MHZ分开安装,之间通过高压软管连接;

最大驱动气压:6bar或8bar;

冲压力:2KN-2000KN。

特殊用途:一只气液增力缸装置可同时驱动多个工作缸同时同步工作。工作缸可选用与一般气液增力缸相似的MAT型缸,也可选用我们特殊设计制造的MHT型液压缸;

可通过一只二位五通主控气阀,即可实现整套气液增力缸的动作控制。

供货包括:气液增力装置MES及MAT型工作缸或MHZ型工作缸。MES与工作缸之间通过高压软管连接起来。高压软管的接头形式及管长可由用户确定。配置有快进行程到力行程的自动转换控制及其转换速度调节阀“X",也可根据您的具体要求,提供特殊的组配,请查询。

MAT型工作缸

型号:

|

行tk程m

|

FKH

t

|

FEH

kgf

|

FRH

kgf

|

V

Cm3

|

△V1

Cm3

|

△V2

Cm3

|

E

|

D

|

C

|

A

|

V

|

B

|

H

|

S

|

F

|

K

|

G

|

N

|

U

|

X

|

MAT1

|

50

|

1.3

|

69

|

72

|

0.31

|

0.6

|

0.4

|

50

|

229

|

6-M6*11

|

40

|

G1/8

|

30

|

10

|

16

|

36

|

M12*1.5

|

12

|

14

|

6

|

G1/2

|

MAT1

|

100

|

1.3

|

69

|

72

|

0.31

|

1.0

|

0.4

|

50

|

329

|

6-M6*11

|

40

|

G1/8

|

30

|

10

|

16

|

36

|

M12*1.5

|

12

|

14

|

6

|

G1/2

|

MAT1

|

200

|

1.3

|

69

|

72

|

0.31

|

1.8

|

0.4

|

50

|

529

|

6-M6*11

|

40

|

G1/8

|

30

|

10

|

16

|

36

|

M12*1.5

|

12

|

14

|

6

|

G1/2

|

MAT1

|

250

|

1.3

|

69

|

72

|

0.31

|

2.3

|

0.4

|

50

|

629

|

6-M6*11

|

40

|

G1/8

|

30

|

10

|

16

|

36

|

M12*1.5

|

12

|

14

|

6

|

G1/2

|

MAT2

|

50

|

2.1

|

140

|

150

|

0.49

|

0.8

|

0.7

|

70

|

242

|

6-M8*12

|

54

|

G1/4

|

40

|

10

|

20

|

41

|

M16*1.5

|

15

|

17

|

8

|

G1/2

|

MAT2

|

100

|

2.1

|

140

|

150

|

0.49

|

1.4

|

0.7

|

70

|

342

|

6-M8*12

|

54

|

G1/4

|

40

|

10

|

20

|

41

|

M16*1.5

|

15

|

17

|

8

|

G1/2

|

MAT2

|

200

|

2.1

|

140

|

150

|

0.49

|

2.6

|

0.7

|

70

|

542

|

6-M8*12

|

54

|

G1/4

|

40

|

10

|

20

|

41

|

M16*1.5

|

15

|

17

|

8

|

G1/2

|

MAT2

|

300

|

2.1

|

140

|

150

|

0.49

|

3.9

|

0.7

|

70

|

742

|

6-M8*12

|

54

|

G1/4

|

40

|

10

|

20

|

41

|

M16*1.5

|

15

|

17

|

8

|

G1/2

|

MAT4

|

50

|

4.2

|

180

|

195

|

1.02

|

2.3

|

0.7

|

85

|

258

|

6-M8*15

|

64

|

G3/8

|

50

|

10

|

30

|

48.5

|

M22*2

|

20

|

24

|

10

|

G1/2

|

MAT4

|

100

|

4.2

|

180

|

195

|

1.02

|

3.1

|

0.7

|

85

|

355

|

6-M8*15

|

64

|

G3/8

|

50

|

10

|

30

|

48.5

|

M22*2

|

20

|

24

|

10

|

G1/2

|

MAT4

|

200

|

4.2

|

180

|

195

|

1.02

|

5.6

|

0.7

|

85

|

555

|

6-M8*15

|

64

|

G3/8

|

50

|

10

|

30

|

48.5

|

M22*2

|

20

|

24

|

10

|

G1/2

|

MAT4

|

300

|

4.2

|

180

|

195

|

1.02

|

8.1

|

0.7

|

85

|

755

|

6-M8*15

|

64

|

G3/8

|

50

|

10

|

30

|

48.5

|

M22*2

|

20

|

24

|

10

|

G1/2

|

MAT4

|

400

|

4.2

|

180

|

195

|

1.02

|

10.6

|

0.7

|

85

|

955

|

6-M8*15

|

64

|

G3/8

|

50

|

10

|

30

|

48.5

|

M22*2

|

20

|

24

|

10

|

G1/2

|

MAT8

|

50

|

8.1

|

320

|

330

|

1.96

|

5.6

|

0.9

|

110

|

288

|

6-M10*16

|

88

|

G1/2

|

70

|

10

|

45

|

60

|

M30*2

|

25

|

36

|

12

|

G3/4

|

MAT8

|

100

|

8.1

|

320

|

330

|

1.96

|

5.7

|

0.9

|

110

|

371

|

6-M10*16

|

88

|

G1/2

|

70

|

10

|

45

|

60

|

M30*2

|

25

|

36

|

12

|

G3/4

|

MAT8

|

200

|

8.1

|

320

|

330

|

1.96

|

10.4

|

0.9

|

110

|

571

|

6-M10*16

|

88

|

G1/2

|

70

|

10

|

45

|

60

|

M30*2

|

25

|

36

|

12

|

G3/4

|

MAT8

|

300

|

8.1

|

320

|

330

|

1.96

|

15.0

|

0.9

|

110

|

771

|

6-M10*16

|

88

|

G1/2

|

70

|

10

|

45

|

60

|

M30*2

|

25

|

36

|

12

|

G3/4

|

MAT8

|

400

|

8.1

|

320

|

330

|

1.96

|

19.7

|

0.9

|

110

|

971

|

6-M10*16

|

88

|

G1/2

|

70

|

10

|

45

|

60

|

M30*2

|

25

|

36

|

12

|

G3/4

|

MAT15

|

50

|

15.8

|

450

|

550

|

3.85

|

9.2

|

1.1

|

135

|

293

|

6-M16*25

|

100

|

G1/2

|

75

|

15

|

50

|

61

|

M30*2

|

25

|

41

|

16

|

G1

|

MAT15

|

100

|

15.8

|

450

|

550

|

3.85

|

10.1

|

1.1

|

135

|

381

|

6-M16*25

|

100

|

G1/2

|

75

|

15

|

50

|

61

|

M30*2

|

25

|

41

|

16

|

G1

|

MAT15

|

200

|

15.8

|

450

|

550

|

3.85

|

19.7

|

1.1

|

135

|

581

|

6-M16*25

|

100

|

G1/2

|

75

|

15

|

50

|

61

|

M30*2

|

25

|

41

|

16

|

G1

|

MAT15

|

300

|

15.8

|

450

|

550

|

3.85

|

28.1

|

1.1

|

135

|

781

|

6-M16*25

|

100

|

G1/2

|

75

|

15

|

50

|

61

|

M30*2

|

25

|

41

|

16

|

G1

|

MAT15

|

400

|

15.8

|

450

|

550

|

3.85

|

37.0

|

1.1

|

135

|

981

|

6-M16*25

|

100

|

G1/2

|

75

|

15

|

50

|

61

|

M30*2

|

25

|

41

|

16

|

G1

|

MAT30

|

50

|

32.0

|

660

|

930

|

7.85

|

19.3

|

2.2

|

170

|

362

|

6-M20*30

|

132

|

G3/4

|

100

|

18

|

56

|

82

|

M39*2

|

35

|

50

|

22

|

G1

|

MAT30

|

100

|

32.0

|

660

|

930

|

7.85

|

22.5

|

2.2

|

170

|

425

|

6-M20*30

|

132

|

G3/4

|

100

|

18

|

56

|

82

|

M39*2

|

35

|

50

|

22

|

G1

|

MAT30

|

200

|

32.0

|

660

|

930

|

7.85

|

40.4

|

2.2

|

170

|

625

|

6-M20*30

|

132

|

G3/4

|

100

|

18

|

56

|

82

|

M39*2

|

35

|

50

|

22

|

G1

|

MAT30

|

300

|

32.0

|

660

|

930

|

7.85

|

58.4

|

2.2

|

170

|

825

|

6-M20*30

|

132

|

G3/4

|

100

|

18

|

56

|

82

|

M39*2

|

35

|

50

|

22

|

G1

|

MAT30

|

400

|

32.0

|

660

|

930

|

7.85

|

76.4

|

2.2

|

170

|

1025

|

6-M20*30

|

132

|

G3/4

|

100

|

18

|

56

|

82

|

M39*2

|

35

|

50

|

22

|

G1

|

MAT50

|

50

|

49.8

|

720

|

1200

|

12.27

|

34.8

|

2.2

|

200

|

390

|

6-M20*30

|

150

|

G3/4

|

115

|

25

|

63

|

92

|

M42*2

|

40

|

55

|

30

|

G1

|

MAT50

|

100

|

49.8

|

720

|

1200

|

12.27

|

34.8

|

2.2

|

200

|

440

|

6-M20*30

|

150

|

G3/4

|

115

|

25

|

63

|

92

|

M42*2

|

40

|

55

|

30

|

G1

|

MAT50

|

200

|

49.8

|

720

|

1200

|

12.27

|

62.7

|

2.2

|

200

|

640

|

6-M20*30

|

150

|

G3/4

|

115

|

25

|

63

|

92

|

M42*2

|

40

|

55

|

30

|

G1

|

MAT50

|

300

|

49.8

|

720

|

1200

|

12.27

|

90.5

|

2.2

|

200

|

840

|

6-M20*30

|

150

|

G3/4

|

115

|

25

|

63

|

92

|

M42*2

|

40

|

55

|

30

|

G1

|

MAT100

|

100

|

103.0

|

1260

|

2200

|

25.45

|

71.5

|

3.1

|

310

|

534

|

12-M24*40

|

200

|

G1

|

150

|

25

|

100

|

120

|

M64*2

|

60

|

85

|

30

|

G1

|

MAT100

|

200

|

103.0

|

1260

|

2200

|

25.45

|

128.7

|

3.1

|

310

|

734

|

12-M24*40

|

200

|

G1

|

150

|

25

|

100

|

120

|

M64*2

|

60

|

85

|

30

|

G1

|

MAT100

|

300

|

103.0

|

1260

|

2200

|

25.45

|

185.9

|

3.1

|

310

|

934

|

12-M24*40

|

200

|

G1

|

150

|

25

|

100

|

120

|

M64*2

|

60

|

85

|

30

|

G1

|

MAT200

|

200

|

199.4*

|

1760

|

2860

|

38.01

|

178.8

|

3.6

|

420

|

829

|

18-M30*55

|

320

|

G3/4

|

240

|

35

|

150

|

150

|

M80*2

|

80

|

4*ø16

|

30

|

G1

|

MHZ型工作缸

型号:

|

行程

mm

|

FKH

t

|

KEH

kgf

|

FRH

kgf

|

V

Cm3

|

△V1

Cm3

|

△V2Cm3

|

E

|

D

|

C

|

A

|

V

|

B

|

H

|

S

|

F

|

M

|

L

|

N

|

P

|

I

|

U

|

W

|

MHZ5

|

50

|

4.8

|

115

|

90

|

2.0

|

2.2

|

0.5

|

65

|

176

|

6-M8*12

|

54

|

G3/8

|

40

|

10

|

25

|

25

|

M12*1.5

|

28

|

19

|

12

|

15

|

8

|

G1/2

|

MHZ5

|

100

|

4.8

|

115

|

90

|

2.0

|

4.3

|

0.5

|

65

|

226

|

6-M8*12

|

54

|

G3/8

|

40

|

10

|

25

|

25

|

M12*1.5

|

28

|

19

|

12

|

15

|

8

|

G1/2

|

MHZ5

|

150

|

4.8

|

115

|

90

|

2.0

|

6.5

|

0.5

|

65

|

276

|

6-M8*12

|

54

|

G3/8

|

40

|

10

|

25

|

25

|

M12*1.5

|

28

|

19

|

12

|

15

|

8

|

G1/2

|

MHZ5

|

200

|

4.8

|

115

|

90

|

2.0

|

8.6

|

0.5

|

65

|

326

|

6-M8*12

|

54

|

G3/8

|

40

|

10

|

25

|

25

|

M12*1.5

|

28

|

19

|

12

|

15

|

8

|

G1/2

|

MHZ7

|

50

|

7.6

|

185

|

130

|

3.1

|

3.4

|

0.6

|

80

|

194

|

6-M8*16

|

65

|

G3/8

|

52

|

10

|

35

|

25

|

M12*1.5

|

28

|

30

|

12

|

18

|

10

|

G3/4

|

MHZ7

|

100

|

7.6

|

185

|

130

|

3.1

|

6.9

|

0.6

|

80

|

244

|

6-M8*16

|

65

|

G3/8

|

52

|

10

|

35

|

25

|

M12*1.5

|

28

|

30

|

12

|

18

|

10

|

G3/4

|

MHZ7

|

150

|

7.6

|

185

|

130

|

3.1

|

10.3

|

0.6

|

80

|

294

|

6-M8*16

|

65

|

G3/8

|

52

|

10

|

35

|

25

|

M12*1.5

|

28

|

30

|

12

|

18

|

10

|

G3/4

|

MHZ7

|

200

|

7.6

|

185

|

130

|

3.1

|

13.7

|

0.6

|

80

|

344

|

6-M8*16

|

65

|

G3/8

|

52

|

10

|

35

|

25

|

M12*1.5

|

28

|

30

|

12

|

18

|

10

|

G3/4

|

MHZ11

|

50

|

10.8

|

260

|

210

|

4.4

|

4.9

|

0.6

|

90

|

194

|

6-M10*16

|

68

|

G3/8

|

52

|

10

|

35

|

25

|

M12*1.5

|

28

|

30

|

12

|

18

|

12

|

G3/4

|

MHZ11

|

100

|

10.8

|

260

|

210

|

4.4

|

9.7

|

0.6

|

90

|

244

|

6-M10*16

|

68

|

G3/8

|

52

|

10

|

35

|

25

|

M12*1.5

|

28

|

30

|

12

|

18

|

12

|

G3/4

|

MHZ11

|

150

|

10.8

|

260

|

210

|

4.4

|

14.6

|

0.6

|

90

|

294

|

6-M10*16

|

68

|

G3/8

|

52

|

10

|

35

|

25

|

M12*1.5

|

28

|

30

|

12

|

18

|

12

|

G3/4

|

MHZ11

|

200

|

10.8

|

260

|

210

|

4.4

|

19.4

|

0.6

|

90

|

344

|

6-M10*16

|

68

|

G3/8

|

52

|

10

|

35

|

25

|

M12*1.5

|

28

|

30

|

12

|

18

|

12

|

G3/4

|

MHZ19

|

50

|

19.2

|

465

|

350

|

7.9

|

8.6

|

0.7

|

125

|

215

|

6-M16*25

|

100

|

G1/2

|

75

|

10

|

50

|

28

|

M20*1.5

|

30

|

41

|

14

|

24

|

16

|

G1

|

MHZ19

|

100

|

19.2

|

465

|

350

|

7.9

|

17.3

|

0.7

|

125

|

265

|

6-M16*25

|

100

|

G1/2

|

75

|

10

|

50

|

28

|

M20*1.5

|

30

|

41

|

14

|

24

|

16

|

G1

|

MHZ19

|

150

|

19.2

|

465

|

350

|

7.9

|

25.9

|

0.7

|

125

|

315

|

6-M16*25

|

100

|

G1/2

|

75

|

10

|

50

|

28

|

M20*1.5

|

30

|

41

|

14

|

24

|

16

|

G1

|

MHZ19

|

200

|

19.2

|

465

|

350

|

7.9

|

34.5

|

0.7

|

125

|

365

|

6-M16*25

|

100

|

G1/2

|

75

|

10

|

50

|

28

|

M20*1.5

|

30

|

41

|

14

|

24

|

16

|

G1

|

MHZ29

|

50

|

30.0

|

720

|

580

|

12.3

|

13.5

|

0.7

|

160

|

298

|

6-M20*30

115

|

G3/4

|

80

|

15

|

55

|

47

|

M39*2

|

35

|

50

|

--

|

27

|

22

|

G1

|

MHZ29

|

100

|

30.0

|

720

|

580

|

12.3

|

27.0

|

0.7

|

160

|

348

|

6-M20*30

|

115

|

G3/4

|

80

|

15

|

55

|

47

|

M39*2

|

35

|

50

|

--

|

27

|

22

|

G1

|

MHZ29

|

150

|

30.0

|

720

|

580

|

12.3

|

40.6

|

0.7

|

160

|

398

|

6-M20*30

|

115

|

G3/4

|

80

|

15

|

55

|

47

|

M39*2

|

35

|

50

|

--

|

27

|

22

|

G1

|

MHZ29

|

200

|

30.0

|

720

|

580

|

12.3

|

54.1

|

0.7

|

160

|

448

|

6-M20*30

|

115

|

G3/4

|

80

|

15

|

55

|

47

|

M39*2

|

35

|

50

|

--

|

27

|

22

|

G1

|

MHZ48

|

50

|

49.2

|

1182

|

887

|

20.1

|

22

|

0.7

|

200

|

300

|

6-M20*30

|

150

|

,, , G3/4

|

125

|

25

|

80

|

60

|

M64*2

|

60

|

70

|

--

|

27

|

30

|

G1

|

MHZ48

|

100

|

49.2

1182

|

887

|

20.1

|

44

|

0.7

|

200

|

350

|

8-M20*30

|

150

|

G3/4

|

125

|

25

|

80

|

60

|

M64*2

|

60

|

70

|

--

|

27

|

30

|

G1

|

MHZ48

|

150

|

49.2

|

1182

|

887

|

20.1

|

66

|

0.7

|

200

|

400

|

8-M20*30

|

150

|

G3/4

|

125

|

25

|

80

|

60

|

M64*2

|

60

|

70

|

--

|

27

|

30

|

G1

|

MHZ48

|

200

|

49.2

|

1182

|

887

|

20.1

|

88

|

0.7

|

200

|

450

|

8-M20*30

|

150

|

G3/4

|

125

|

25

|

80

|

60

|

M64*2

|

60

|

70

|

--

|

27

|

30

|

G1

|

MHZ74

|

50

|

77.0

|

1847

|

1385

|

131.4

|

35

|

0.7

|

275

|

366

|

12-M24*40

|

200

|

G3/4

|

150

|

25

|

100

|

65

|

M64*2

|

60

|

85

|

--

|

27

|

30

|

G1

|

MHZ74

|

100

|

77.0

|

1847

|

1385

|

131.4

|

70

|

0.7

|

275

|

416

|

12-M24*40

|

200

|

G3/4

|

150

|

25

|

100

|

65

|

M64*2

|

60

|

85

|

--

|

27

|

30

|

G1

|

MHZ74

|

150

|

77.0

|

1847

|

1385

|

131.4

|

105

|

0.7

|

275

|

466

|

12-M24*40

|

200

|

G3/4

|

150

|

25

|

100

|

65

|

M64*2

|

60

|

85

|

--

|

27

|

30

|

G1

|

MHZ74

|

200

|

77.0

|

1847

|

1385

|

131.4

|

140

|

0.7

|

275

|

516

|

12-M24*40

|

200

|

G3/4

|

150

|

25

|

100

|

65

|

M64*2

|

60

|

85

|

--

|

27

|

30

|

G1

|

MES系列气液增力装置

订购号:

|

6par气压时最大油压

|

用于快进行程的输送油量(ml)

|

用于力行程的输送油量(ml)

|

A

|

B

|

C

|

D

|

E

|

型号

|

MES100

|

200

|

450

|

44

|

110

|

560

|

242

|

76

|

G1/2

|

MES125

|

200

|

710

|

75

|

135

|

580

|

272

|

82

|

G1/2

|

MES160

|

190

|

1180

|

130

|

172

|

630

|

260

|

85

|

G3/4

|

MES200

|

210

|

2700

|

275

|

219

|

799

|

363

|

95

|

G1

|

MES250

|

200

|

4070

|

395

|

267

|

810

|

339

|

105

|

G1

|

MES300

|

185

|

5120

|

370

|

324

|

1463

|

386

|

135

|

G2

|

MES320

|

190

|

6230

|

475

|

351

|

1456

|

377

|

140

|

G2

|

特殊用途的ODMT气液增力缸

加配“负压消除装置”的ODMT气液增力缸

安装在ODMT气液增力缸内部的负压消除装置,可避免在某些加工过程中高压腔内突然出现低压或负压,保障气液增力缸长期连续正常工作。

此类气液增力缸主要用于冲裁加工。

加配“回程液压缓冲装置”的ODMT气液增力缸

安装在ODMT气液增力缸内部的回程液压缓冲装置,可有效地减缓气液增力缸在高频速度工作中的回程冲击,延长使用寿命,降低噪声。

此类缸主要用于运动速度快的场合。

首页

首页